The quality of the products is strictly controlled from the first step to each step. Each batch of products has a detailed quality file with a traceability period Up to five years.

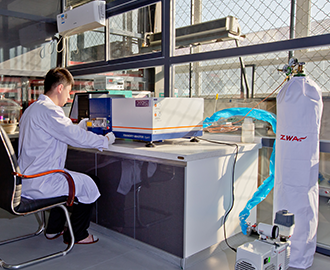

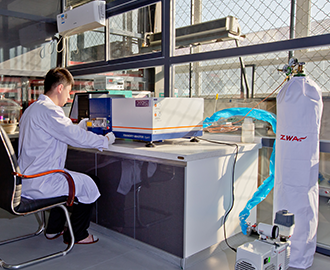

Oxford direct reading spectrometer, Germany

Test Items £ºCapable of detecting bearing steel material in Fe, Cu base, chemical elements.

Function £ºPut an end to unqualified material and steel elements the use of steel, to ensure the service life of bearing.

Feature £ºHigh measurement precision, saves the argon gas.

Remark (Type code) £ºFOUNDRY-MASTER Xpert

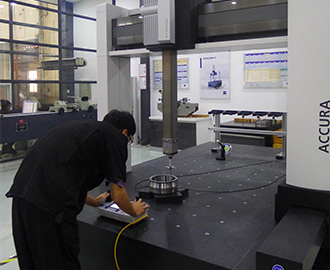

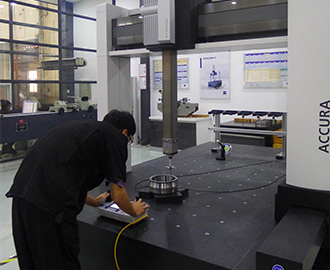

German Zeiss three coordinates

Test Items £ºProbe contact testing which can accurately test the precision of dimension, shape, position and runout of all kinds of complicated parts.

Function £ºAn intelligent tool devoted to the bearing design, development, testing and statistical analysis.

Be able to accurately test the dimension, shape, position, runout etc of bearing rings, cages and other parts. An effective instrument guaranteeing the product quality with wide testing function and application

Feature £ºHigh testing precision and good repeatability; big board guarantees the wide testing scope; surrounded gas bearings are applied on the three axles make the operating flexible; continuous scanning makes the testing fast and accurate; self calibration; temperature compensation device can guarantee the accurate testing on the dimension without heat preservation condition.

Remark (Type code) £ºACCURA12/24/10

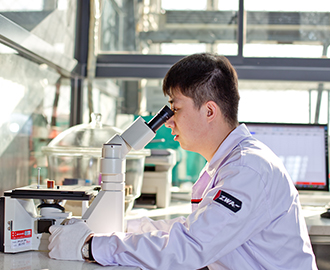

Germany leica microscope

Test Items £ºMetallographic test

Function £ºTest the carbide?lamellartiy, network,?eliquation and inclusion of raw material; organization of heat treatment and annealing to guarantee the qualification of raw material and life of bearings.

Feature£ºSoftware: geometric testing, setting on printing copies, special module, rated level. Hardware: LED light source

Remark (Type code) £ºDMILM LED

CNC vertical grinding machine

Test Items£ºCNC grinding equipment adopting Siemens CNC operating system. Positioned by electromagnetic coreless fixture and easier to operatePrecision can be reached over level P4.

Function £ºGrinding the surface, inner diameter, outer diameter, inner raceway, outer raceway, flange of ball, spherical roller, cylindrical roller and tapered roller bearings. All grinding process of bearings can be realized in this equipment.

Feature £ºMulti-function; high production precision; reduce error on the positioning; positing multi surface at a time.